Explore our products

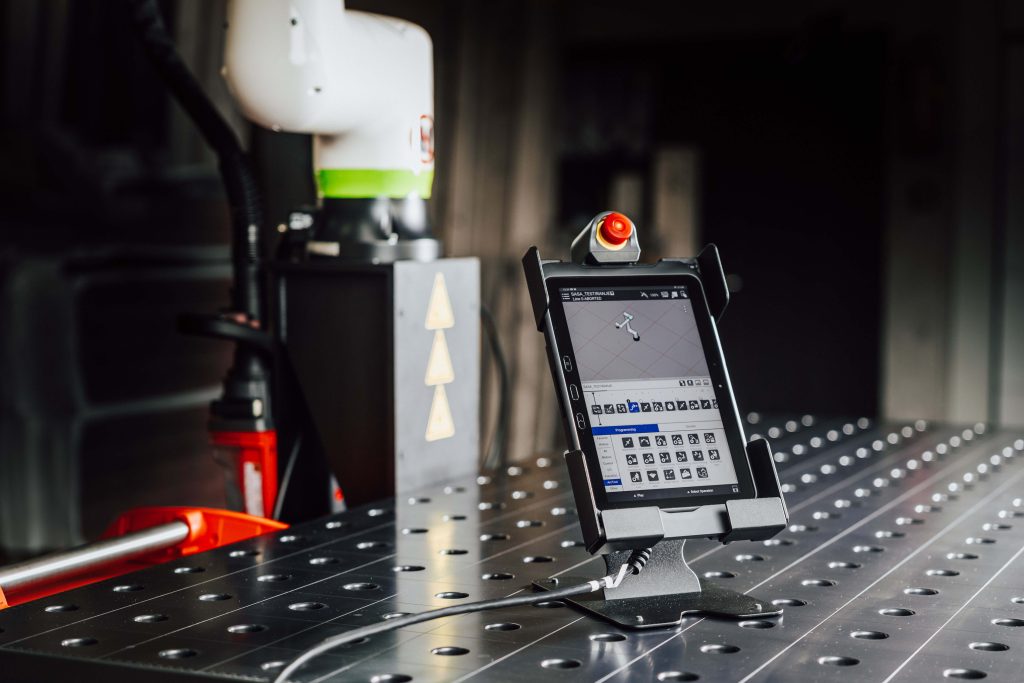

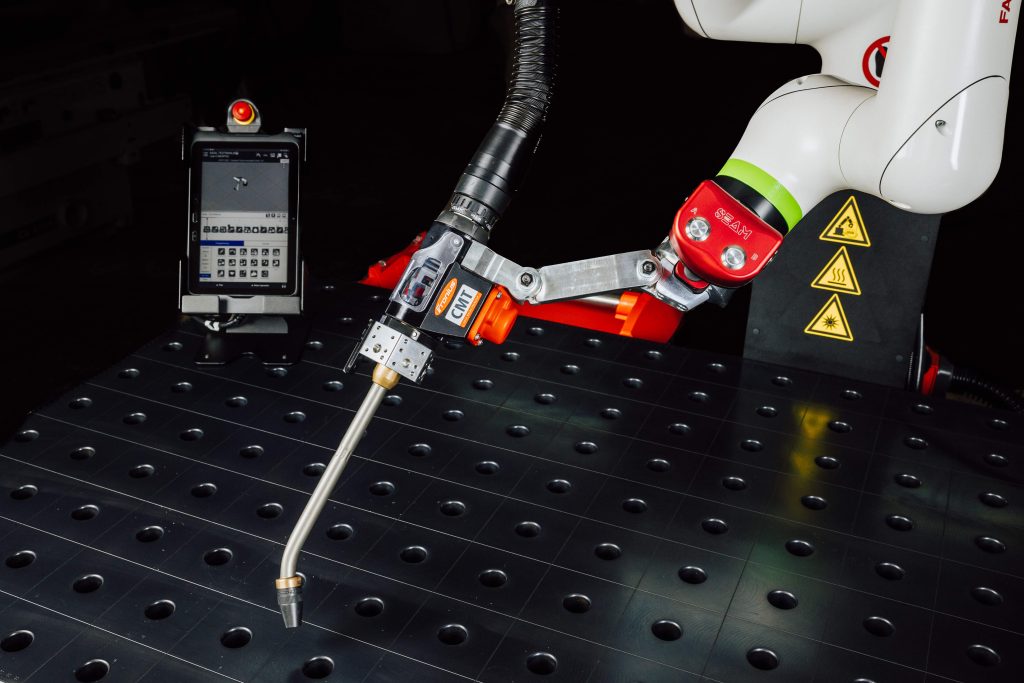

Cobot Welding Cell

A revolution in industrial welding – flexibility, safety, and efficiency through collaborative robotics.

The cobot welding cell is an advanced solution that combines automation precision with human interaction flexibility. Thanks to collaborative robots (cobots), welding processes can be automated without the need for complex safety barriers, saving space and increasing safety in the work environment

Key Advantages:

- Easy integration into existing production lines

- Fast operator training without programming knowledge

- High weld quality with repeatability and precision

- Increased productivity with reduced labor costs

- Safe operation alongside humans, thanks to advanced sensors and collision avoidance systems

Flexible Configuration:

The cobot welding cell can be designed to be:

- Fixed, with one or two worktables

- Compact and mobile, for easy relocation within the production facility

- Mounted on an additional linear rail of various lengths, tailored to your requirements

- Combined with rotary tables, enabling welding of complex geometries and multi-sided joints

Welding Processes:

The cobot welding cell supports various welding technologies:

- MIG/MAG welding

- TIG welding

- Laser welding

- Multiprocess configuration, where a single cobot can perform all listed processes with quick and easy torch change, providing maximum flexibility and efficiency

Applications:

Cobot welding cells are ideal for serial production, as well as flexible tasks in small and medium-sized enterprises. They are used in:

- Automotive industry

- Metalworking plants

- Machinery and structural manufacturing

- Any environment requiring reliable and high-quality welding technology

Why Choose a Cobot Welding Cell?

In a world that demands rapid market adaptation, cobot welding cells enable agile production, reduce the need for manual labor, and increase competitiveness. With low initial investment and simple maintenance, this is a solution that pays off quickly

💬 Interested in a cobot welding cell?

Contact us for free consultations and discover how collaborative welding technology can enhance your production

IPG Photonics LightWELD®

LightWELD® handheld laser welding and cleaning devices are fast, easy to learn and operate, and produce high quality, consistent results across a wide range of materials and thicknesses. Pre-weld and post-weld laser cleaning functionality optimizes weld quality while increasing productivity

GRIP

Specialized in intelligent tool changers (EOAT) and robotic grippers

Our tool changer systems significantly improve the functionality and increase the possibilities of robots in industrial handling technology applications. This helps increase productivity and flexibility in automated manufacturing and production environments.

- Increased flexibility through easy tool changing

- Reduced downtimes thanks to automatic tool changing

- Processes are performed with the highest level of precision

- Safe tool change of heavy or potentially dangerous tools